Sodium acetate didn’t pop out of nowhere. Its salt roots stretch back to alchemists in Europe and makers of vinegar in Asia. Early records speak about “vinegar salts” turning up in dye works and food preserves, long before the chemical market gave it a proper name. Makers heated vinegar with sodium carbonate or sodium hydroxide, scooping useful white crystals for everything from dye-bath fixes to textile print paste. Chemists picked up the pace in the 19th and 20th centuries. They tightened up the formulas, learned more about purity, and delivered sodium acetate with fewer leftovers from other reactions. Over time, a humble byproduct from vinegar shops spread out, stepping into labs, classrooms, industrial floors, and even heating pads tossed into backpacks.

Sodium acetate shows up in two usual forms: the anhydrous powder and the clear, chunkier trihydrate. Countless companies sell both, but the trihydrate runs most of the action because it stays stable, easy to store, and useful in bulk. Its commercial production still leans on a simple trick—mix acetic acid (main part of vinegar) with a sodium base like baking soda or sodium hydroxide, then dry or crystallize as needed. Uses range far and wide. Food techs use it as a flavoring or acidity buffer, while labs keep jars handy for DNA extraction, buffer prep, titration, and calibration. The granular or blocky trihydrate brings the best value for schools and industrial users, but powder or tablets help field workers and hospitals, looking for quick, measured dosing.

Clear, colorless crystals (or a soft white powder), sodium acetate trihydrate smells faintly like vinegar if anyone gets close enough. It melts around 58°C, dissolving easily in water to make a nearly neutral solution, with a pH right at 7-8 for a one-molar mix. It doesn’t catch fire, doesn’t eat through gloves, and doesn’t put off fumes at typical use temperatures. Unlike sodium chloride, salt’s rougher cousin, sodium acetate won’t pull much water out of the air, so clumping remains rare in dry rooms. This comes in handy for storage. Chemically, the acetate part makes it a mild base, able to buffer acids and bases in equal measure. Its stability stays high even after months on a shelf, with a shelf-life measured in years if kept sealed against dampness.

Factories don’t cut corners on purity, as impurities in sodium acetate can mess up reactions, especially in medicine and biotech. Labels usually print purity grades: technical, food, and pharmaceutical. Tech grade suits cleaning and industrial jobs. Food grade lands in snacks, flavor blends, and baked goods. Pharmaceutical grade covers injectable solutions or DNA work. Labels must also show moisture content, since the trihydrate holds about 38% water by weight, while the anhydrous powder contains next to none. Hazard and storage warnings follow country rules, with most packs listing batch number, expiry, and handling notes for workers. The United States Pharmacopeia (USP) sets tough limits for heavy metal contamination and bacterial counts in the purest grades.

Making sodium acetate at home or factory follows a simple two-ingredient process: acetic acid and a basic sodium compound. Most large plants tip acetic acid into a reaction tank, followed by careful addition of sodium carbonate or sodium hydroxide. The solution fizzes up as carbon dioxide escapes or heat builds from the reaction. After this bubbling, producers concentrate the liquid, then cool it until pure sodium acetate crystals form. Workers scoop or filter out the crystals, then rinse and dry. Tiny makers, including students at home, sneak by with vinegar as the acid and baking soda for sodium—foaming happens, and the remaining solution crystallizes overnight as the water evaporates. Getting it pure as labs require takes extra work, with controlled pH, steady temperatures, and careful drying under vacuum.

Mix sodium acetate with heat, and it can break apart, leaving carbon, water, and that familiar acetic acid tang. The compound holds its own as a buffer, keeping lab reactions stable when acids or bases swing in. Acetate ions hook up with metals, forming metal-acetate complexes. These have uses in making catalysts, dyes, and plating baths. Heating concentrated sodium acetate with strong acids gives off acetic acid vapors, used in old-school chemistry for vinegar essence. In other setups, swapping acetate out for more reactive chemicals leads into territory making esters, plastics, or drugs. Scientists pick the compound for its reliability—its reactions rarely surprise, and it supports a huge toolbox of classic organic experiments.

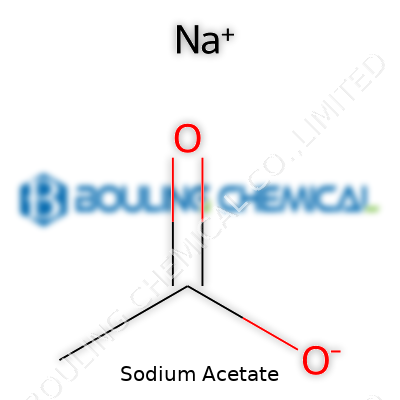

Doctors, chemists, and warehouse crews all use different names for this same salt, but the chemical formula stays put: CH3COONa. Marketplace labels read “sodium ethanoate” in British labs or “vinegar salt” around kitchens. Some packagers write “E262” to mark food-grade use in the European Union. The trihydrate sometimes appears as “sodium acetate, crystalline” while powders take “anhydrous sodium acetate.” In trade, expect longer phrases like “buffer solution, sodium acetate” or “hot pack sodium acetate” for thermal safety tools. Local brands stamp their own logos, but the list of synonyms stays pretty short if buyers need to match up chemicals for school kits or compliance documents.

Most safety handbooks show little worry with sodium acetate in normal use. The powder can sting eyes and irritate bare skin, but not at hazardous levels. Customary lab gear—gloves, goggles, and dust masks—handle the risk factor. In industry, food inspectors check for cross-contamination with common allergens or heavy metals. Storage habits play a bigger part. Staff seal containers tight, keep them in dry, shaded storage, and label everything to avoid mistakes with similar-looking salts. Restaurants and snack makers check each shipment for purity as set by the Food Chemicals Codex and the FDA. Factories follow ISO standards and country rules for workplace training and first-aid plans, even if sodium acetate’s main risk has more to do with slipping on spilled crystals than any long-term poisoning.

Sodium acetate holds a surprising range of day-to-day roles. The food world mostly sprinkles it in as a preservative and flavor booster for chips, snacks, and pickled goods. Fast food’s “salt and vinegar” flavor owes much to sodium acetate’s subtle tang. Textile dyers use it to control the pH in dye baths. Chemists and biotechnologists depend on its buffer strength for controlling the acidity of lab reactions—critical for DNA isolation, protein purification, and cell culture work. Hot packs for muscle pain rely on sodium acetate’s ability to “freeze” into a warm gel, releasing measured heat for minutes or hours without wires or batteries. In water treatment, the salt acts as a feedstock for bacteria cleaning up industrial waste. School classrooms use it for simple crystal-growing projects, and hobbyists even shape it into flexible “ice” molds or heat pads for winter hunting trips.

Innovation doesn’t slow down with such a common salt. In my time working with environmental engineers, sodium acetate proved valuable in wastewater treatment, where researchers keep searching for greener, cheaper carbon sources to feed helpful bacteria. As battery makers look at flow and solid-state designs, some teams test sodium acetate brines for safe, low-cost electrolyte solutions. Scientists in pharmaceuticals use improved grades of sodium acetate for advanced crystallization—a key step for antibiotic production and protein therapies. Some research stretches to materials science, where new heat pack designs use sodium acetate in flexible films or self-healing pads. All of this relies on solid chemical knowledge, careful control of manufacturing sources, and independent purity checks to avoid trouble in sensitive applications.

No major red flags rise in animal tests with sodium acetate at the doses used in food and labs. Acute oral toxicity for rats sits high, with effects seen only at large doses. Human exposure from daily use—on skin or through food—rarely hits problem levels. Even long research projects report nothing significant for long-term consequences when sodium acetate stays below maximum residue levels set by agencies such as the European Food Safety Authority or the U.S. FDA. A few cases trace mild digestive or skin discomfort to direct, heavy exposure. Researchers who test genetic and cancer risks keep updating their reviews, but as of now, sodium acetate remains far safer than dozens of other basic salts and nearly all synthetic preservatives. Wastewater from factories manages with standard release permits, as sodium acetate breaks down quickly in the environment without piling up downstream.

Growth for sodium acetate won’t hit headlines, but its uses keep evolving. Environmental engineers count on this humble salt to improve bioreactor output, clean water, and lower treatment costs. The healthcare sector wants better hot packs and IV solutions using sodium acetate blends, while food science teams test more compatible flavor agents that work with new food trends. Battery designers eye it for cheap, stable storage in grid-scale systems—resistant to fire and drought. New manufacturing tech will likely create purer grades faster, with finer control of crystal size and energy use. Regulatory authorities will revisit safety data, adding stricter batch testing as more fields rely on reproducible results. If the past two centuries built a foundation, the next decades will test sodium acetate’s flexibility, from the world’s biggest wastewater plants down to classrooms and home kitchens, bridging old chemistry with new environmental and health needs.

Sodium acetate rarely gets a headline, but it shows up in places most of us wouldn’t expect. As a food ingredient, I first noticed it listed on the back of a salt and vinegar chips bag. The label might spark concern, though it’s added mainly for flavor. Unlike some chemical-sounding names in snack food, sodium acetate stems from acetic acid—the same stuff in vinegar. It provides that tangy taste without making chips soggy. Chips stay crisp, my lunch feels less like a science project, and food producers get longer shelf life without odd-smelling preservatives.

Not every use involves food. One winter, I slipped a small pouch into my pocket before heading outside. Clicking a metal disc inside that pouch started a rapid reaction—the liquid inside turned solid and hot within seconds. Those hand warmers use sodium acetate’s unique property: it forms a supersaturated solution that solidifies and releases heat on cue. The comfort I got from thawing my fingers, just walking my dog, made me appreciate how practical chemistry improves daily life.

Hospitals also take advantage of sodium acetate, but for medical reasons. Saline drips sometimes must be changed to balance the body’s acid levels. Rather than reaching for strong acids or bases, clinicians often pick a solution containing sodium acetate, especially for those struggling with metabolic acidosis. Research supports this choice: a study in the New England Journal of Medicine points to sodium acetate’s effectiveness in helping maintain healthy pH levels during certain treatments, minimizing the risks linked with harsher chemicals.

At home, sodium acetate finds its role in cleaning products. Many glass and surface cleaners depend on acetate compounds to break down grime without corroding surfaces like harsher substances do. With a vinegar-like smell and the ability to dissolve mineral deposits, sheds, and kitchen tiles all benefit from this gentle touch. As someone who has scrubbed a fair share of shower heads, I appreciate a product that can clear up limescale without etching the metal.

In textile production, sodium acetate keeps dyes from fading. It stabilizes pH during the dye process, ensuring that colors stay bright after repeated washes. When I dyed fabric at home, I noticed commercial kits included it for just this reason—strong colors meant less wasted effort. Industries also use sodium acetate to tan leather and process photographic films. Its ability to buffer pH makes it valuable for products that need reliable performance.

Classrooms across the world often show kids how sodium acetate “hot ice” works. Teaching students to see science hands-on, teachers count on safe demonstrations that spark curiosity about phase change, crystallization, and energy. Watching clear liquid snap into solid crystals never fails to catch the attention of curious kids. This early spark may even get some students thinking more about science as a future calling.

Sodium acetate may come from simple ingredients, but its roles keep expanding. From food prep to healthcare, from staying warm to keeping fabric bright, this compound proves that science solves everyday problems even if the solutions quietly blend into daily routines. People deserve to know more about the chemistry woven into their lives. Product labels can put that information in our hands in words we understand. Schools can use simple demonstrations to show young minds where science leads. By sharing honest stories and facts, we get everyone on board with the things that make life safer, easier, and a little more interesting.

Sodium acetate shows up in a lot of places—packaged foods, instant heating pads, pickles. If you have eaten salt-and-vinegar chips or looked at the ingredient list for some processed cheeses, you might have noticed it. It delivers that classic tartness some folks crave and helps extend shelf life, which attracts food companies aiming to curb waste and cut costs.

I grew up sneaking chips from the kitchen while doing homework, not realizing sodium acetate was part of that tangy punch. Curiosity led me to dig into what this ingredient actually does and why food scientists pick it over other options.

Our bodies know what to do with sodium acetate. The compound splits into sodium, benefitting muscle function, and acetate, a form of short-chain fatty acid the body can process for energy. The U.S. FDA places sodium acetate on its GRAS (Generally Recognized As Safe) list for food uses. Europe’s food safety agency agrees, using the E262 label for sodium acetate in food manufacturing. Studies have not flagged big health concerns at the concentrations approved for snacks, cheeses, or sauces.

The numbers say something too: toxicology research shows only extreme doses—much higher than dietary exposure—cause health problems like nausea or imbalance in blood chemistry. For people without health issues such as kidney problems or sodium-sensitive hypertension, sodium acetate in moderation does not raise red flags.

That said, moderation stands out as a point, just like with table salt. Too much sodium acetate can drive up sodium intake, which links to raised blood pressure and risk of heart disease, a fact widely recognized by experts from organizations such as the American Heart Association. Processed foods pack in sodium from many sources, not just sodium acetate, so it pays to read labels and stay informed.

Some people worry about how “food additives” sound technical or unfamiliar. The real concern arrives when eating patterns push sodium above recommended limits. Still, a single ingredient like sodium acetate cannot be isolated as the sole threat. A bigger problem appears in the shape of overall processed food consumption and lifestyle choices.

Trust is built through transparency and quality evidence. Reading ingredient labels is one starting point. If you want to cut sodium, cooking at home more, favoring fresh produce, and limiting processed snacks remains the most effective approach. Those with heart, kidney, or blood pressure concerns should talk with their doctor. For most people, sodium acetate in ordinary amounts won’t tip the balance if the overall diet stays wholesome.

Researchers keep tabs on new findings and regulatory agencies review scientific evidence. If any concerns about sodium acetate’s safety surface, food laws will update. Until then, keeping a balanced approach, seeking variety, and knowing what goes into packaged foods will go farther than fearing one unfamiliar ingredient.

Sodium acetate, a familiar sight in many labs and classrooms, often gets overlooked in safety conversations. Years spent around busy storerooms and even messy middle school science bins have taught me that just because something sounds harmless, it doesn’t mean it deserves less care. People use sodium acetate in everything from heating pads to food flavoring, but skipping proper storage invites trouble—clumping, spills, even damaged equipment. Mishandling leads to wasted materials, ruined experiments, and sometimes unexpectedly risky reactions.

One of the trickiest parts with sodium acetate stems from its sensitivity to moisture. Open a bag on a humid day, and soon clumps appear, making measurements less accurate. Sometimes, I’ve scooped into what looked like sugar only to find chunks that refused to dissolve in water. Moisture sneaks in fast, especially in places with damp air or leaky ceilings. Dry, airtight containers save a lot of hassle. Glass jars with tight-fitting lids, sealed plastic tubs, or thick polypropylene bags hold up better than thin, flimsy packaging.

Labels get overlooked too. Forgetting what’s inside, or when it was last opened, quickly leads to mistakes. I've learned to make labeling a non-negotiable step, using bold writing and dating the container. This helps avoid confusion between a lab-grade chemical and something less pure used in cooking.

Storage area choice makes a bigger difference than many expect. I’ve seen what happens when containers sit near radiators or sunny windows—sometimes they melt, other times contents degrade. Hot spots create condensation inside containers, wrecking even the driest batch of sodium acetate. Instead, finding a cool, shaded shelf out of direct sunlight keeps the powder dry. Metal cabinets in utility rooms often work well. I always check for any signs of leaks or spills nearby, so chemicals stay apart from stuff they could react with.

Daily routines go a long way. After dipping into a jar or scooping powder for a project, I run a dry cloth along the rim and close the lid tight. Once, someone left a cap loose for just an afternoon, and the powder clumped hard enough to throw away the whole jar. Just a couple of minutes spent tidying up pays off down the line.

Chemical safety instructions often feel dry, but sodium acetate’s potential for skin or eye irritation means it shouldn’t be treated as just another pantry staple. Gloves help, as does keeping the area clean so nothing else gets mixed in by accident. Storing it away from acids, flammable liquids, or substances prone to react with it avoids cross-contamination and any weird surprises. One spill caused a sticky mess in my own classroom, and clearing it up took longer than if we had just stuck to routine checks and sensible storage.

Using desiccant packs or silica gel in storage containers proves more helpful than most realize, especially in damp climates. If a space lacks air conditioning or experiences temperature swings, extra care and thicker packaging really pay off. Making a shared checklist posted above the shelf can remind everyone in busy workspaces to tighten lids, check for leaks, and wipe down containers before putting them back.

Lastly, reviewing storage rules every so often keeps them from fading into the background. It takes just one misstep to lose an entire container or, worse, risk a health issue. Good storage habits mark the line between a safe, productive lab—or kitchen—and a string of preventable accidents.

Sodium acetate, written as CH3COONa, shows up in all sorts of places. The formula breaks down simply: a combo of sodium (Na), two carbons, three hydrogens, and two oxygens. What matters most is not just these letters and numbers, but the uses behind them. In school, I remember teachers describing it as “table salt with a twist” because of that sodium base joined to an acetate group. Sodium comes from the alkali metals, notorious for sparking in water, while the acetate part traces back to vinegar. This isn’t just trivia; knowing what's in sodium acetate steers its applications far beyond academic whiteboards.

Sodium acetate’s formula turns up everywhere from heating pads to kitchen tricks. Those reusable hand warmers in winter? That warmth flows from this chemical. The solution, supersaturated with sodium acetate, snaps into a solid with the push of a small metal disk, releasing steady heat. This reaction only happens because the chemical structure works just right. I remember using one during a snowy football game, and the comfort it brought wasn’t abstract science—it was chemistry in action. In cooking, food scientists use it to mimic the sharp twang of salt and vinegar chips. In textile manufacturing, it keeps dyes from blotching. Simple changes in the formula produce forms that shape industries quietly but persistently.

Schools drill chemical formulas into kids, but there’s more to sodium acetate than a test question. Industrial plants need quality checks to ensure the right balance of ions, especially for safe production in heating or food. Mistakes in mixing chemicals with the wrong ratios can endanger workers or spoil a batch. Regulatory groups share the same concerns. The Food and Drug Administration looks for clear documentation not only of CH3COONa but also of contaminants that might sneak into industrial batches. Tracing the chemical formula back to raw materials adds layers of safety for everyone involved, from factory teams to families at home.

Not every sodium acetate batch works as planned. Contamination or confusion with other sodium salts creates headaches, risking product recalls or public trust. Even in the world of science outreach, mislabeling can keep kids from seeing just how vibrant chemistry can be. One way forward lies in clearer lab training, better labels, and updated quality control routines. I lost more than a few lab points in college by flipping numbers in a chemical formula, but later noticed the difference a double-check and honest group discussions made. Repetition and a culture of correction keep the focus on accuracy, which ripples out into safer, more reliable uses of sodium acetate everywhere.

Details inside a formula look tiny. For sodium acetate, though, each letter represents a story of practicality, invention, or an everyday fix. More than just a string of atoms, the formula CH3COONa stands as a lesson in asking deeper questions, checking your work, and recognizing chemistry’s role outside cramped lab benches. Young students, teachers, factory technicians, parents—they all use information about this formula in different ways, and getting it right pays off in very real ways. Focusing on the basics, but not getting stuck there, grounds progress, safety, and curiosity in ways that matter.

Sodium acetate shows up in science classrooms, food factories, textile companies, and even some pretty clever hand warmers. My first experience with it came in a makeshift lab, trying to whip up instant “hot ice” demonstrations for a high school open day. Later, I noticed the same stuff listed on the back of bags of salt and vinegar chips. Whether you’re preparing experiments, running small manufacturing projects, or simply curious about food additives, sodium acetate’s popularity comes from its flexibility.

The first stop for most shoppers is the internet. Websites like Amazon, eBay, and Walmart offer various grades of sodium acetate, often sold as powder, crystals, or hydrated flakes. Each source lists the intended use—so the label will mention if it’s for science demonstration kits, laboratory research, or food processing. I’ve found that sticking to sellers that provide safety data sheets shows real professionalism. These documents reveal purity levels, handling advice, and whether the product fits your needs.

Science classroom experiments spark curiosity, and specialty suppliers fill this gap. In my town, local science education stores keep sodium acetate in stock for demonstrations like “hot ice” or safe acid-base reactions. Online companies including Flinn Scientific and Carolina Biological Supply stand out for educators and home experimenters. Prices run higher than bulk sellers, but these stores package chemicals safely and offer better guidance.

For larger orders, chemical distributors such as Spectrum Chemical or Fisher Scientific take bulk buyers seriously. Food-grade sodium acetate draws interest from restaurant suppliers, especially pickling companies and chip makers. Industrial chemical outlets demand business information and may ask about your intended use before selling. As a small manufacturer, I had to show proof of business and sometimes a tax ID. This extra paperwork lets them keep a watchful eye on buyers and make sure hazardous materials don’t slip through the cracks.

I’ve walked up and down pharmacy aisles looking for sodium acetate with zero luck. Most pharmacies choose not to carry it, preferring common compounds like citric acid or baking soda. Hardware stores often come up empty-handed for specialty chemicals, focusing on salt for ice melting or basic cleaning supplies. Chain superstores and hardware giants usually point customers to their websites, which in turn, send shoppers back to third-party sellers.

Sodium acetate doesn’t seem risky at first. But buying from unknown online sources puts you at risk for mystery substances and unreliable purity. Reputable outlets back up their products with lot numbers, certificates, and return policies. For scientific or food uses, contamination can spoil an experiment or cause health concerns. Information from the American Chemical Society supports this: purity and traceability count just as much as price tags. My own habit now? I choose brands with a track record and reviews from other buyers who outline their experiences in detail.

Easy availability of basic chemicals plays a role in education, business, and research. Responsible sourcing keeps the system honest. Buyers can ask sellers for details, request documentation, and keep chemicals labeled and safe. For those curious enough to try their hand at home science, stick to reputable science education brands. Businesses and food makers should never skip safety and paperwork for the sake of a cheaper deal.

Getting sodium acetate isn’t just about scrolling through listings or asking a clerk. It’s about looking for quality, understanding legal concerns, and thinking ahead to safe storage. Whether for science, food, or industry, informed buying turns a routine purchase into something smarter and safer for everyone involved.

| Names | |

| Preferred IUPAC name | Sodium ethanoate |

| Other names |

Sodium ethanoate

Acetic acid sodium salt Ethanoic acid sodium salt |

| Pronunciation | /ˈsəʊdiəm əˈsiːteɪt/ |

| Identifiers | |

| CAS Number | 127-09-3 |

| Beilstein Reference | 3568736 |

| ChEBI | CHEBI:32139 |

| ChEMBL | CHEMBL1357 |

| ChemSpider | 5313497 |

| DrugBank | DB09210 |

| ECHA InfoCard | 100.011.268 |

| EC Number | 204-823-8 |

| Gmelin Reference | 1265 |

| KEGG | C01342 |

| MeSH | D013063 |

| PubChem CID | NaN |

| RTECS number | AJ4300010 |

| UNII | NSV44423JL |

| UN number | UN3077 |

| Properties | |

| Chemical formula | C2H3NaO2 |

| Molar mass | 82.03 g/mol |

| Appearance | White crystalline powder |

| Odor | slight acetic odor |

| Density | 1.528 g/cm³ |

| Solubility in water | Very soluble |

| log P | -4.21 |

| Vapor pressure | <0.01 mmHg (20 °C) |

| Acidity (pKa) | 4.76 |

| Basicity (pKb) | 9.25 |

| Magnetic susceptibility (χ) | -39.7×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.422 |

| Viscosity | 1.05 mPa·s (at 20 °C, for a 10% solution) |

| Dipole moment | 2.97 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 86.3 J·K⁻¹·mol⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −711 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -947.7 kJ/mol |

| Pharmacology | |

| ATC code | B05XA04 |

| Hazards | |

| Main hazards | May cause eye, skin, and respiratory tract irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Warning |

| Hazard statements | Hazard statements: "May cause respiratory irritation. |

| Precautionary statements | P264, P270, P301+P312, P330, P501 |

| Autoignition temperature | > 607 °C (1125 °F; 880 K) |

| Explosive limits | Non-explosive |

| Lethal dose or concentration | LD50 (oral, rat): 3530 mg/kg |

| LD50 (median dose) | 3530 mg/kg (rat, oral) |

| NIOSH | SN1225000 |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | 0.3 mg/m³ |

| IDLH (Immediate danger) | Not listed |

| Related compounds | |

| Related compounds |

Sodium formate

Sodium propionate Potassium acetate |