Propyl acetate entered the industrial landscape as chemists searched for effective and affordable solvents in the late 19th and early 20th centuries. Companies valued its balanced volatility and pleasant fruity smell, factors that set it apart from more pungent, dangerous solvents. In my work with coatings and paints, I've seen how the switch from older, more toxic compounds toward more user-friendly options typically followed broad public health trends. As solvents like benzene fell out of favor for their severe health impacts, industries pivoted toward esters like propyl acetate. Historical patents trace its uses across varnish formulations, flavoring agents, and extraction processes, illustrating how necessity and safety attitudes often drive chemical innovation.

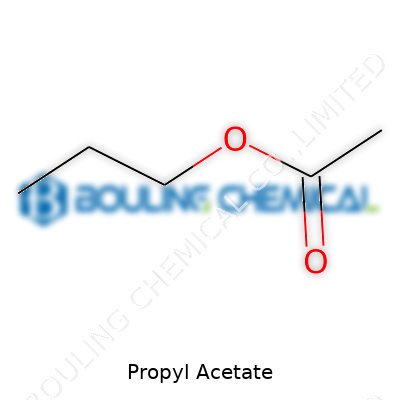

Propyl acetate belongs to the ester family and comprises a colorless, flammable liquid with a smell reminiscent of pears. It finds a home in paint thinners, nail polish removers, and even some artificial flavors. As a mid-range solvent, it brings a good evaporation rate, striking a balance between drying speed and manageable worker exposure. Its place in manufacturing lines connects directly to its physical characteristics and straightforward preparation. The chemical shows up under several guises in commercial supply catalogs, but the core utility stays constant—it's the go-to for fast-acting, easy-to-handle solvent work.

Propyl acetate's molecular formula stands as C5H10O2, and it tips the scale at a molecular weight around 102 grams per mole. It boils close to 102°C, with moderate water solubility and a vapor pressure making it neither the quickest to leave a film nor the hardest to push out in drying tunnels. Its refractive index sits at 1.387, while its density lands at 0.88 g/cm³. From my own bench-scale syntheses, I appreciate how often these physical details correlate with real-world handling: lighter than water, propyl acetate floats and spreads swiftly, and its moderate polarity lets it dissolve oils but also evaporate cleanly from surfaces.

The industry sets typical purity standards above 99% for propyl acetate used in high-end applications such as pharmaceuticals or electronics. Labels must spell out flammability risks, handling instructions, and possible health effects. Regulatory bodies like OSHA and the European Chemicals Agency recommend flash point notations, hazard pictograms, and emergency exposure limits. Reliable labels ensure that plant workers, transporters, and end-users know what they're working with, minimizing both mishaps and confusion. Every barrel rolling onto a truck tells a story not just of scientific progress, but also of risk management and daily practicalities.

I watched once as a team ran the classic Fischer esterification to make propyl acetate, combining acetic acid and n-propanol with sulfuric acid as a catalyst. This method, still widely favored in industry, takes advantage of strong acid to speed up the reaction and push the equilibrium toward ester formation. Some plants recycle acetic acid from wood-pulping or fermentation byproducts, while others source propanol from petrochemical streams. In recent years, pressure from both regulators and customers gave new life to "greener" production routes—biobased feedstocks and less waste-intensive workflows. Still, the core chemistry hasn't shifted much. Process engineers work to optimize yield, purify the product, and neutralize byproducts, keeping efficiency and worker safety front and center.

Propyl acetate sits at a chemical intersection and takes part in hydrolysis under alkaline or acidic conditions, breaking down to acetic acid and propanol. In industrial spills, this reaction spells out clean-up challenges if caustic soda or acids are involved. I've used it as a reactant in transesterification, blending it with other alcohols or acids to make different ester products—tailoring odor and solvency for a particular job in paints or adhesives. Exposure to reducing agents, or high temperatures, can tear apart its structure, which is why plant operators keep close watch on both process variables and waste streams.

This chemical often appears under names like 1-propyl acetate, n-propyl ethanoate, or even 'pear oil' in older food additive registrations. Different countries, suppliers, and industries give it other trade names, sometimes causing confusion when ordering supplies or checking compliance documentation. For example, European buyers might see EC numbers or REACH registration codes as the main identifier, whereas North American catalogs lead with CAS numbers. Naming conventions can get tangled, so experience—and double-checking chemical structures—goes a long way.

Safety data sheets emphasize that propyl acetate is flammable, with vapors forming explosive mixtures above 9.5% in air. Anyone handling bulk quantities relies on spark-proof equipment, good ventilation, and personal protective gear. Short-term inhalation can dull reflexes or cause headaches, and long exposure can dry out skin or irritate eyes. As someone who's loaded drums in a paint factory, I learned to respect protocols—no shortcuts, no sparking tools, and careful attention to spill trays. Fire codes demand foam or CO2 extinguishers on hand, and every drum's grounding wire gets checked twice.

Paints, inks, and coatings make up the lion's share of demand for propyl acetate, taking advantage of its balanced evaporation for smooth, even film-forming. I've watched print shops rely on it to keep press rollers clean without the health headaches of older solvents. Nail polishes use it for high-gloss, fast-drying finishes. Food-grade batches—made under tighter GMP controls—serve as flavor additives, bringing a fruity kick to candies or chewing gum. Extraction and purification chemists also count on propyl acetate to separate natural products or pharmaceuticals, thanks to its moderate partitioning power.

Companies push the boundaries with new propyl acetate blends, looking for ways to combine high solvency power with lower toxicity. Research teams explore enzyme-driven synthesis routes, seeking higher yields at gentler conditions. Academics map out detailed environmental fate profiles, since regulators now demand proof that solvents break down safely or bio-accumulate minimally. Cheminformatics studies highlight propyl acetate’s role as a model molecule for simulating ester behavior in reactive coatings, adhesives, and biofuel blends. From patents to academic papers, the search for safer, more effective, and greener processes shows no sign of slowing down.

Toxicologists log animal studies and epidemiological data, and conclusions keep shifting as testing grows more rigorous. Propyl acetate breaks down in the body to acetic acid and propanol, both of which the liver typically handles well at low doses. High vapor concentrations present inhalation risks, causing drowsiness, respiratory irritation, or central nervous system depression in extreme situations. Chronic exposure studies on factory workers hint at higher asthma rates or skin sensitization, so companies set strict exposure limits and ventilation requirements. Regulatory agencies call for updated toxicological assessments as logic and analytical methods evolve, holding producers and processors accountable for both worker and community safety.

As green chemistry grows in importance, manufacturers bet on biorenewable raw materials and cleaner synthesis techniques. My experience with greener solvents showed that customer loyalty shifts not just for better performance, but also for products carrying environmental certifications. Electronics makers look for solvents with fewer volatile organic emissions, and consumers ask more questions about what goes into their beauty or home products. Advances in catalyst design, enzyme engineering, and recycling continue to push propyl acetate production toward lower waste and higher sustainability. While new regulations and competitive pressures keep everyone on their toes, the fundamentals remain—everyone wants safer, cleaner, and more efficient ways to put propyl acetate’s best qualities to work.

Propyl acetate sounds like something you’d find lurking in a chemistry lab, but it shows up in everyday life far more often than most folks realize. It’s a colorless liquid with a smell that reminds me of pears and a little bit like nail polish remover. Yes, that pear hint isn’t a coincidence—propyl acetate gives pears much of their scent. In nature, some fruits let out propyl acetate as they ripen, calling out to us with that juicy, sweet aroma.

In the industrial world, propyl acetate’s claim to fame comes from its work as a solvent. I remember walking through a printing press in college, and the sweet chemical smell in the air was unmistakable—propyl acetate helps inks do their job. Printers lean on this substance because it dries quickly, doesn’t leave behind sticky residue, and keeps colors sharp. Without a solid solvent, ink can’t stick to paper evenly, which means blurry text, fuzzy graphics, and wasted paper.

In manufacturing, propyl acetate finds its way into paints, coatings, and adhesives. Spray painters favor it because it lets paint flow smooth and dry at a good pace. Makers of artificial leathers and certain plastics have relied on it for similar reasons. It’s not just about being a jack-of-all-trades, though. Propyl acetate evaporates almost as fast as isopropyl alcohol, yet it manages to leave a more pleasant scent behind. Folks working with it daily often comment on this.

These days, most people think “chemical” means danger, but propyl acetate has made its way into flavor and fragrance circles, too. Regulatory agencies like the FDA have it listed as safe for use in food, as long as the amount stays tiny. Flavorists reach for it to put the finishing “pear drop” note into candies and drinks. Perfumers use it to round out fruit scents—your shampoo or soap might just owe its fresh aroma to a dash of propyl acetate.

Propyl acetate isn’t without risks. Breathing in too much can make you dizzy, and it can irritate the eyes or skin. In my brief job at a paint supply store, we wore gloves and made sure storage tanks were tightly sealed. Propyl acetate catches fire at lower temperatures, so good ventilation and basic fire prevention can’t be taken lightly. Still, with the right handling, the health impact remains low for users and workers.

Critics sometimes worry about environmental harm, but compared to tougher solvents like xylene or toluene, propyl acetate breaks down swiftly in the air and water. It doesn’t last long enough to build up or trickle down into drinking water in meaningful amounts. Regulators keep tight watch, though, and new production techniques cut down on emissions during manufacturing.

Propyl acetate might not get headlines, but industries lean on it for speed, performance, and even safety. For small-scale workers and consumers, knowing where it pops up—on a paint can label or in a perfume ingredient list—lets us make better choices. Staying mindful of proper handling, better ventilation, and greener production can keep propyl acetate useful for years to come, without tipping the balance toward harm. As someone who’s handled more than a few buckets of paint in my time, I can say that knowing what’s inside makes all the difference.

Propyl acetate runs common in labs and some factories, showing up in paints and coatings, or as a flavoring agent. The thing most folks miss—this solvent brings a strong, fruity smell, but also a pretty serious risk of harm, especially if handled without care. Working with it taught me quickly one careless step can lead to headaches, dizziness, or irritated skin. That sharp tingle on the hands lingers. Its vapors do a number on your lungs faster than you’d expect, and the fire risk hovers constantly in the back of the mind.

Propyl acetate evaporates quickly. Wearing gloves, goggles, and a sturdy lab coat is not for show. Bare skin sucks up this chemical far too easily. Even thin gloves, like nitrile, hold up well against splashes, while basic latex breaks down. Eyes sting and water with even a minor splash—goggles stop a painful and dangerous accident.

It’s not just about protecting skin or eyes. Vapors build up without warning if the space doesn’t move air well. A snug-fitting respirator and fume hood keep your lungs safe. Years in a lab, I saw co-workers underestimate air movement only to end up light-headed and coughing. That warning label shouldn’t be ignored.

Flammable chemicals like propyl acetate never belong near open flames or warmth. Some people think a tightly closed cap solves it all, but the real risk comes from its ability to seep fumes. Flammable storage cabinets built for solvents cut down that danger. Always separate chemicals that react with acids or strong bases to prevent surprise reactions. Leaky bottles or damaged containers don’t stay in backrooms—they go right to hazardous waste.

Air mixes with propyl acetate vapors to form a major fire risk. Sparks from electrical tools or static electricity, a cigarette left burning, or careless use of open flames can cause explosions or fires. Long ago, a loose wire above a worktable led to a flash fire that cleared half the building before anyone could react. Grounding your equipment and never using the chemical near ignition sources cuts out the worst accidents.

Every spill gets treated like a hazard, even if it’s just a little puddle. Soaking up with absorbent materials, moving waste to sealed bags, and keeping them in approved drums avoids the spread of flammable vapors. Big spills mean alerting emergency response immediately—trying to mop up a floor-wide spill with paper towels is a rookie mistake. In busy shops, having spill kits on-hand, with clear instructions, proved priceless more than once.

Many accidents come from not knowing the risks. I’ve watched new hires dip hands into cleaning tubs without gloves, not realizing what they waded into. Training goes deeper than a manual; regular drills make instincts kick in during emergencies. Good signage, Safety Data Sheets posted right where people work, and direct conversations about near-misses build a respect for the chemical’s danger and help everyone avoid costly errors.

Propyl acetate isn’t a monster if you respect it. Clear protocols, the right safety gear, and some real attention to detail keep the work healthy—for both people and the buildings they work in.

Propyl acetate turns up in paints, printing inks, nail polish removers, and many products with a sweet, fruity scent. It’s that fresh pear aroma in some artificial flavors. Plenty of people cross paths with this chemical every day without thinking twice. But just because something smells nice doesn’t make it harmless.

My first real run-in with propyl acetate came during a summer renovation job in college. After hours of sanding and repainting, my nose tingled and my eyes pricked. Propyl acetate vapor causes eye, nose, and throat irritation. Spend a few hours in a poorly ventilated room filled with this stuff, and it sneaks up with headaches and dizziness. OSHA and other agencies have set exposure limits for a reason. Inhalation strips away more than just comfort—prolonged or heavy exposure can trigger coughing, lightheadedness, and even trouble breathing.

Anyone who has handled industrial solvents knows that gloves are worth their weight in gold. Propyl acetate pulls moisture from skin, leaving it dry, red, and itchy. Over time, repeated contact stirs up dermatitis. Some folks shrug off a rash or burn as part of the job, but ignoring symptoms often leads to worse trouble down the road. Children or workers with sensitive skin are at even greater risk, especially if safety gear gathers dust in the supply closet.

This chemical doesn’t just vanish after use. In the air, propyl acetate breaks down fairly quickly, but it can add to ground-level ozone, contributing to smog—a problem city dwellers already know all too well. If cleaning rags soaked in solvent end up in the trash, improper disposal means the chemical might seep into waterways, harming aquatic life. Fish and insects don’t cope well with solvents, even diluted ones. Tiny spills at home add up across neighborhoods, especially when storm drains take everything straight to the river.

Turning the tide doesn’t ask for rocket science; simple habits make a difference. Work with propyl acetate? Crack open a window or use an exhaust fan, and don’t skip the gloves or goggles. Municipal hazardous waste programs keep leftovers out of landfills and water. Reading product labels and opting for low-VOC or “green” alternatives helps cut total exposure at home. In the shop, storing chemicals tightly capped and away from kids or pets keeps everyone out of harm's way.

I’ve had projects where a strong-smelling paint made working miserable, only to find better ventilation or a different product made a world of difference. Parents, workers, and property managers all play a role. By paying attention, asking suppliers about safer products, and supporting policies that limit harmful solvents in everyday products, we can lower the risks for everyone—the folks using them and those living nearby. Small changes stack up over time, keeping both people and the planet a little healthier.

Propyl acetate finds its way into nail polish removers, paints, printing inks, and plenty of other common industrial products. It doesn’t hang around long out in the open, evaporating with a sweet fruity smell. Most users don’t spend much time thinking about its shelf life. After years working in a lab, I’ve seen that ignoring proper storage can lead to wasted product, damaged equipment, and risky situations for staff.

Manufacturers often recommend storing propyl acetate for up to 12 months before it starts to break down. That number doesn’t mean it magically spoils the next day. Shelf life depends on how people treat it before opening the cap and after resealing it. Propyl acetate reacts to oxygen, heat, and even traces of moisture in the air. If the container sits half-empty, air sneaks in every time someone pours a little out. This slow dance with the environment can change the chemistry. It may look, pour, and smell the same, but the purity drops over time. Allergic reactions and equipment failures sometimes creep up when folks use expired chemical batches.

My lab once tried to save a few bucks by holding onto an older drum. At first, nothing seemed out of place. In the next batch, the end product changed color and fouled up the filters. We traced the problem to impurities that crept in after months of careless storage. The money we thought we saved vanished fast in wasted materials and lost production time.

Chemicals like propyl acetate sound scary only when folks ignore basic safety. I’ve seen that just a few simple steps can save headaches and cut risks down to size. First, always store propyl acetate in airtight, HDPE or stainless steel containers. No crumbling cardboard boxes or used glass bottles. Keep drums and bottles tucked away in cool, shaded areas. Sunlight and heat tend to speed up evaporation and chemical breakdown. I like to keep storage temperatures below 30°C (86°F), far from radiators and heat sources.

Some people think putting containers on concrete works fine, but moisture from the floor can sneak up and corrode metal drums, tainting the chemical inside. Wooden pallets or sturdy shelving keep things dry and tidy. I’ve always made it a point to label every bottle with the date received and opened. That way, any product that sits too long stands out. Good ventilation in storage spaces helps carry away stray vapors, just in case of leaks. Don’t be tempted to leave containers open for easy access—this only invites trouble.

Expired propyl acetate needs careful handling. Tossing it down the drain or mixing it with regular trash can harm both people and the planet. Qualified waste contractors can collect and treat leftover chemicals. Even small-scale operators should check with local regulations before pouring anything away. It’s safer and often required by law.

Most accidents don’t happen because people set out to ignore the rules. They happen when storage instructions get buried in documents or newcomers don’t get proper training. Sharing know-how in regular team meetings or short reminders keeps the right habits fresh. In my experience, the simple act of talking through storage routines in plain language lowers the odds of mistakes and keeps everyone safer—and that goes a lot further than any printed warning label.

Walk into any paint or printing shop, and chances are you’ve smelled that distinct fruity aroma. That’s propyl acetate. As someone who has worked near paint booths, I’ve seen it used for thinning inks and coatings. Many laboratories keep a flask of it around, not just for its pleasant smell, but for its knack for dissolving resins and waxes many other solvents struggle with.

Blending solvents isn’t just chemistry for chemistry’s sake—the end product actually handles differently. If you’re using propyl acetate, you're likely looking for quick drying times and that sweet smell. Still, not every mix goes smoothly. Some blends let you stretch your budget or adjust how fast something dries or dissolves. Others lead to headaches and product recalls.

I’ve come across cases where artists ended up with tacky surfaces and printers found their inks separating. This isn’t just annoying—it can mean ruined jobs. If you know your chemistry, mixing goes beyond tossing bottles together. You look at polarity, boiling points, and flash points.

Propyl acetate gets along with a long list of other solvents. Ethanol, esters like ethyl acetate, ketones such as acetone or methyl ethyl ketone, and aliphatic hydrocarbons all blend well. Its polarity sits somewhere in the middle, so you have room to play around with formulas. A practical perk: propyl acetate doesn’t pick up water easily, so you skip the drama of layering or clouding you see in some blends.

It’s tempting to see that compatibility chart and think you can mix without worry. But I've seen firsthand—especially in workplaces with lax safety rules—where things go sideways. Some solvents, like chlorinated hydrocarbons, can boost toxicity. Others, like highly flammable ones, mean extra fire risks. Any time you mix, you're raising the stakes for ventilation, flash point, and safe storage.

Mixing always brings up the need for facts, not guesswork. For me, pulling a Safety Data Sheet (SDS) is step one. You should know if your mix might form peroxides or if the vapors can knock you out faster than you expect. A solid resource is the National Institute for Occupational Safety and Health (NIOSH), where guidance on exposure and incompatibilities can save you from bad surprises.

Some countries now ask manufacturers to list all possible hazardous reactions when formulating products for sale. This isn’t just bureaucracy; it's about real-world injuries and environmental spills that hit small shops hardest. Years back, an old landlord nearly lost his workshop after a blend ignited from a tiny spark, partly because no one checked compatibility.

The real trick is balancing performance and safety. If you want slower evaporation, you might add a heavier alcohol. Chasing that fast-drying finish? Pair with acetone, but keep an eye on ventilation. Always test in small batches. I’ve watched seasoned chemists lean on years of mixing experience, but even the pros check their references and legal requirements.

Improvement comes from sharing information and sticking to the basics: know your solvents, read your labels, and test on a small scale. If you think “it’ll probably be fine,” you might be setting yourself up for a problem down the line. Honest discussions and curiosity drive better outcomes in both small shops and large factories.

| Names | |

| Preferred IUPAC name | **Propyl ethanoate** |

| Other names |

1-Acetoxypropane

Acetic acid propyl ester n-Propyl acetate Propyl ethanoate |

| Pronunciation | /ˈproʊ.pəl ˈæs.ɪ.teɪt/ |

| Identifiers | |

| CAS Number | 109-60-4 |

| 3D model (JSmol) | `CCCC(=O)O` |

| Beilstein Reference | 635112 |

| ChEBI | CHEBI:8775 |

| ChEMBL | CHEMBL155481 |

| ChemSpider | 6823 |

| DrugBank | DB13815 |

| ECHA InfoCard | ECHA InfoCard: 027-011-00-4 |

| EC Number | 207-088-7 |

| Gmelin Reference | 6074 |

| KEGG | C01063 |

| MeSH | D011378 |

| PubChem CID | 8021 |

| RTECS number | AJ3675000 |

| UNII | N9UOI0476A |

| UN number | UN1276 |

| Properties | |

| Chemical formula | C5H10O2 |

| Molar mass | 102.13 g/mol |

| Appearance | Colorless liquid |

| Odor | fruity |

| Density | 0.888 g/cm3 |

| Solubility in water | Moderate (1.0 g/100 mL at 20 °C) |

| log P | 1.24 |

| Vapor pressure | 18 mmHg (20°C) |

| Acidity (pKa) | pKa ≈ 25 |

| Basicity (pKb) | The basicity (pKb) of propyl acetate is **15.5**. |

| Magnetic susceptibility (χ) | -7.48×10⁻⁶ |

| Refractive index (nD) | 1.388 |

| Viscosity | 0.8 mPa·s (at 20 °C) |

| Dipole moment | 1.78 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 177.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -429.1 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2212.6 kJ/mol |

| Pharmacology | |

| ATC code | V03AB05 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H336 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P271, P280, P303+P361+P353, P304+P340, P312, P305+P351+P338, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 1-3-0 |

| Flash point | 16 °C |

| Explosive limits | 1.7% - 8.0% |

| Lethal dose or concentration | LD50 oral rat 9,370 mg/kg |

| LD50 (median dose) | 7,937 mg/kg (rat, oral) |

| NIOSH | RN36767 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Propyl Acetate is "200 ppm (840 mg/m³) |

| REL (Recommended) | 200 ppm |

| IDLH (Immediate danger) | 1700 ppm |

| Related compounds | |

| Related compounds |

Ethyl acetate

Isopropyl acetate Butyl acetate |